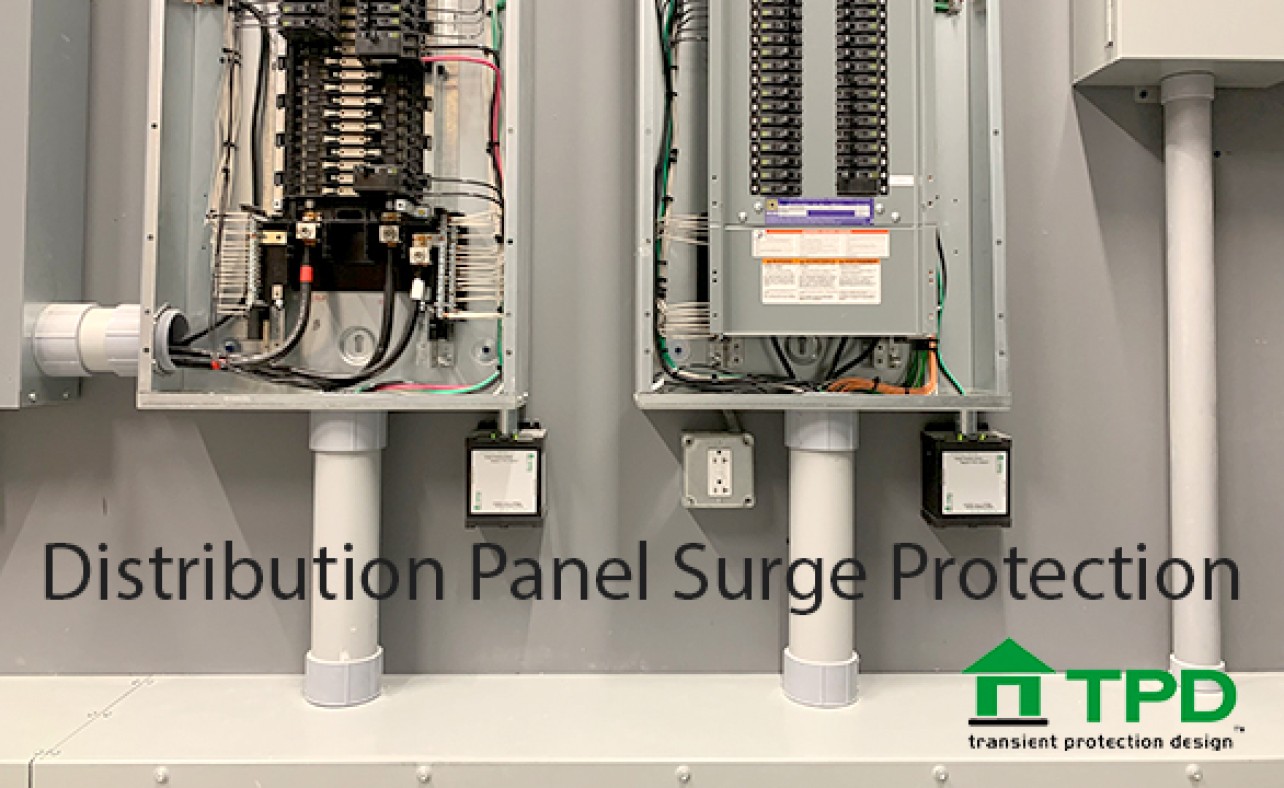

Distribution Panel Surge Protection

Distribution panel surge protection in industrial facilities is a proactive measure that protects electrical infrastructure, minimizes equipment damage, prevents widespread disruptions, enhances operational continuity, extends equipment lifespan, mitigates safety risks, preserves process control, ensures compliance with industry standards, and reduces overall operational costs. It is essential for maintaining the reliability, safety, and efficiency of industrial operations. TPD has distribution panel surge protection devices for all breaker panels, service entrance panels, and distribution panels both indoor and outdoor. Compact design offers easy installation. The optional enhanced transient filter will extend your equipment life and reliability.

15 Year Warranty Including Lightning

UL1283 EMI/RFI Filter

UL1449 5th Edition Surge Suppressor

TYPE 1 & Type 2 SPD

Nema 4 Weatherproof Enclosure

100kA Per Phase

100kAIC Short Circuit Current Rating

Can be installed on any amperage panel

How To Surge Protect Distribution Panels

Distribution panel surge protection provides a second layer of protection after the service entrance. It also address the internally generated transient by equipment withing the facility.

277/480 Volt Panels: TPX-3Y480-F-150

120/208 Volt Panels: TPX-3Y208-F-150

TPX Product Information

| 15 Year Warranty Including Lightning |

| UL1283 EMI/RFI Filter |

| UL1449 5th Edition Surge Suppressor |

| Type 1 & Type 2 SPD |

| Nema 4 Weatherproof Enclosure |

| 100kA Per Phase |

| 100kAIC Short Circuit Current Rating |

| Can be installed on any amperage panel |

The Importance of Distribution Panel Surge Protection

Protecting Electrical Infrastructure

Distribution panels are the central points for distributing electrical power throughout commercial and industrial facilities. Surges can cause damage to circuit breakers, transformers, wiring, and other critical components within these panels. TPD surge protection helps safeguard the electrical infrastructure from costly damage and disruptions.

Minimizing Equipment Damage

Industrial facilities often rely on a wide range of electrical equipment, including motors, control systems, PLCs (Programmable Logic Controllers), LED lighting, and instrumentation. These assets are vulnerable to voltage spikes and surges, which can result in equipment damage or failure. TPD surge protection at distribution panels reduces the risk of costly repairs or replacements.

Preventing Widespread Disruptions

Surges that enter the distribution panel can affect the entire industrial electrical network, impacting various production processes and machinery. TPD surge protection at this central point helps prevent the spread of damaging surges, minimizing downtime and production interruptions.

Enhancing Operational Continuity

Large facility operations often run continuously, and downtime due to electrical issues can be financially devastating. Surge-induced failures can disrupt production, lead to missed production targets, and result in lost revenue. TPD surge suppression filters help maintain uninterrupted operations.

Extending Equipment Lifespan

Frequent voltage surges can accelerate the wear and tear of electrical equipment and components. TPD surge protection not only prevents immediate damage but also extends the overall lifespan of industrial assets, reducing maintenance costs and downtime.

Mitigating Safety Risks

Electrical surges can create hazardous conditions within industrial facilities, including the risk of electrical fires or injuries to personnel. TPD surge protection contributes to safety and compliance with industry standards by reducing the likelihood of electrical hazards associated with surges.

Preserving Process Control

Many industrial processes rely on advanced control and automation systems, which can be sensitive to voltage fluctuations and surges. TPD surge protection safeguards these systems, preventing disruptions, data loss, and process control issues.

Cost Reduction

While surge protection involves an initial investment, it can lead to substantial cost savings over time by reducing equipment replacement costs, downtime-related losses, and maintenance expenses.

The Importance of and EMI/RFI Surge Filter

While the filter does not help against direct lightning strikes and is not as critical in protecting electromechanical devices such as pumps and motors, it is critical in protecting sensitive electronic loads from internally generated ring wave transients. Also, normal load switching of equipment on any panel can surge the loads on the other circuits if no suppressor is placed on that panel. Our units feature filters that are specifically designed to address high frequency internally generated ring wave transients (sometimes referred to as spikes).

In the real world, 80% to 99% of transients are generated inside the facility, almost all are low magnitude, and all propagate throughout the facility as ring wave transients (impulse transients are transformed into oscillatory ringing transients as they move throughout the facility because of the impedance inherent in building wiring). Without a good filter, these transients will adversely affect electronics since almost all ring wave transients would be below the turn-on point of the avalanche diodes and MOVs (metal oxide varistors) that are the main components used in surge suppressors on the market today. Most of the ring wave transients we have seen inside the facility range from 200 volts to 900 volts, with most being in the 200 to 400 volt range. It is the cumulative effect of these internally generated transients that degrade and shorten the life of electronics, including LED drivers. And, these ringing type transients can also cause glitches, lock-ups, and reprogramming issues in PLCs and other electronic equipment.

We assume that most customers interested in the performance of an SPD would want to know how their SPD is going to perform relative to the fact that 80% or more of the transients are internally generated in their facility. This is more critical every year given the explosive growth in micro-processor based/data intensive applications in all of our facilities. Real world transient filtering is imperative for achieving sustainable performance and reliability of these loads.

Externally generated transients such a lightning happen infrequently. But, as long as equipment is operating, internally generated transients are occurring inside a facility and causing gradual degradation to all electric loads. Cleaning up these high frequency but low magnitude ringing transients is the key to reduced maintenance costs, reduced glitches and reprogramming events, and reduced downtime. Most electronic equipment is connected to subpanels or found inside industrial control panels or industrial machines. So, the better the ring wave protection of the SPD protecting the three phase power feeding the panel, the LED lighting, or CNC or other industrial machine, the greater the savings to the facility and the quicker the return on investment.