CNC Surge Protection and Power Filtering

CNC surge protection is crucial because these machines rely on precise electronics and control systems to function. A surge can cause costly downtime, damage sensitive components, disrupt production, and lead to expensive repairs or replacements. CNC machinery, including lathes, milling machines, laser systems, plasma cutters, and 3D printers, holds a pivotal role in modern manufacturing processes. These machines are susceptible to voltage fluctuations, transient spikes, and electrical surges that can result from various sources including lightning strikes, power grid fluctuations, or equipment switching. TPD protects equipment from manufacturers such as Mazak, Haas, Trumpf, DMC, Okuma, Fanuc. Doosan, DMG Mori, Starrag, Liechti, Willemin Macodel, Hermle, and Alzmetall.

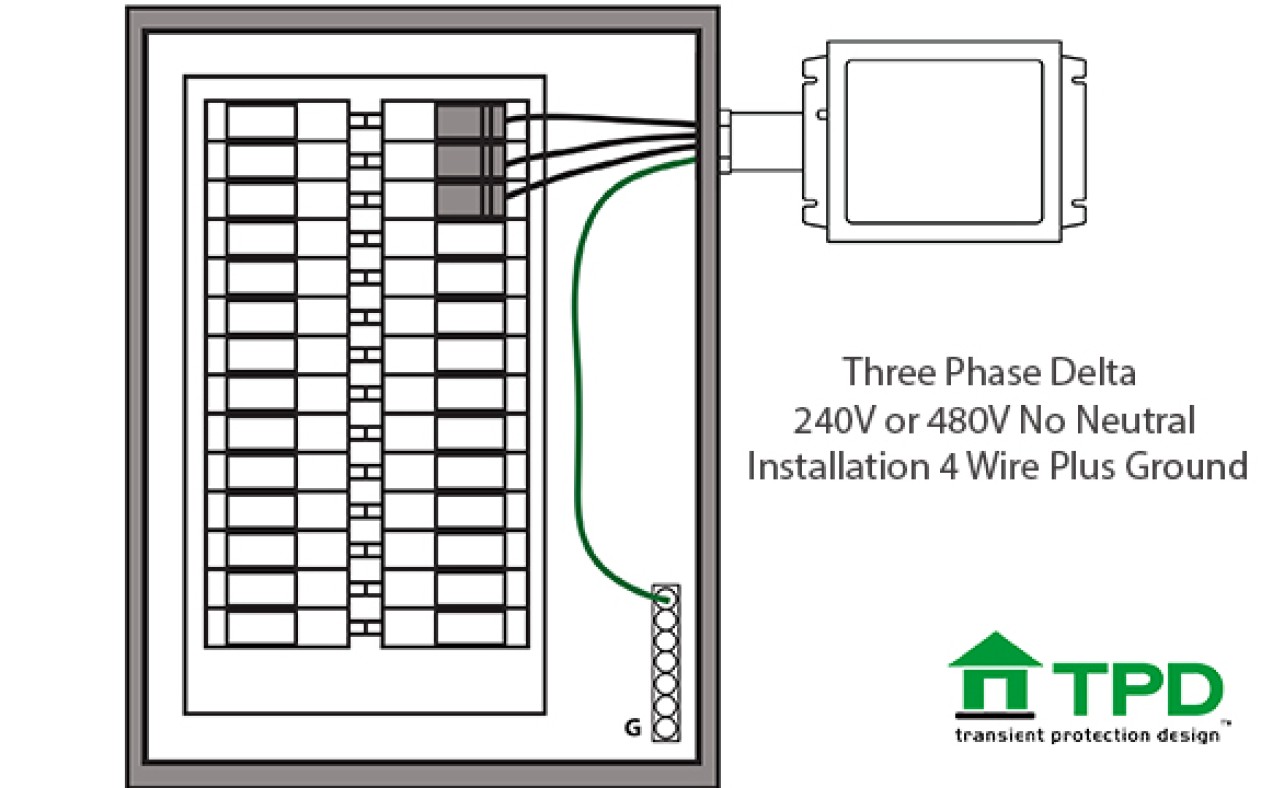

TPX-480NN-F-100 480V No Neutral Panels

TPX-240NN-F-100 240V No Neutral Panels

15 Year Warranty Including Lightning

UL1283 EMI/RFI Filter

UL1449 5th Edition Surge Suppressor

TYPE 1 & Type 2 SPD

Nema 4 Weatherproof Enclosure

100kA Per Phase

100kAIC Short Circuit Current Rating

Can be installed on any amperage panel

How To Surge Protect CNC Machines

The TPX-480NN-F-100 includes surge protection and enhanced filtering protection and can be installed at each CNC. Or, protect multiple CNC machines by installing a surge protector at the panel feeding CNC equipment.

480 Volt No Neutral Machines: TPX-480NN-F-100

240 Volt No Neutral Machines: TPX-240NN-F-100

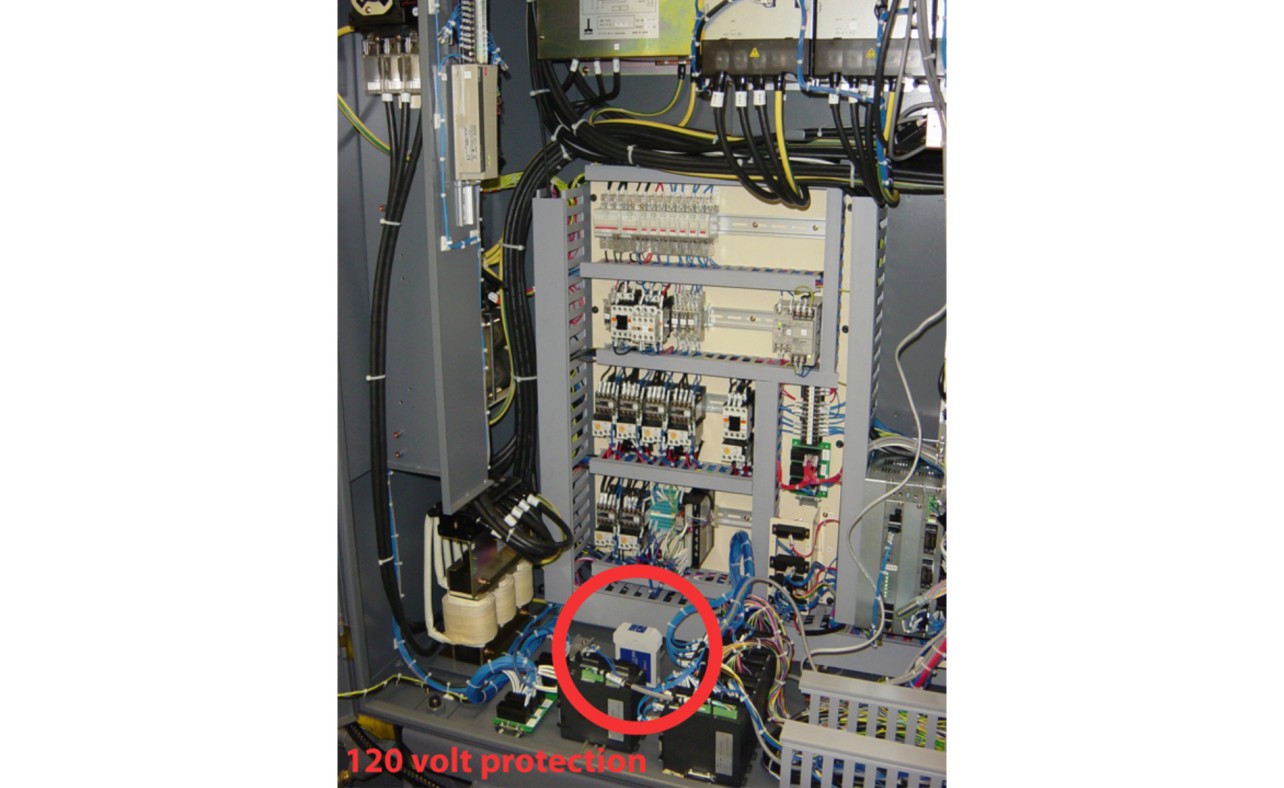

When possible, install a small series wired surge protector unit on the circuit feeding the low voltage controls for additional protection.

Surge Protect 24 Volt Control Circuits: TPD-DM24-15A

More about the TPX No Neutral on CNC Applications:

These surge protection devices provide great protection to any machine tool from lightning, utility surges, and high-speed transients on the three-phase power that directly feeds the CNC machine. Transient Protection Design offers surge suppression products that are easy to install as they can go direct to the bus, disconnect, or any size breaker or fuse block, and can be installed outside or inside the machine. The SPD units are parallel installed, so system amperage is not a factor. This unit has component level internal fusing (100kAIC SCCR) and can be installed on the disconnect feeding the machine or can be installed directly on the machine. Only the units installed at each machine or on each distribution panel directly feeding the machines can stop the internally generated transients. Normal load switching of equipment inside any facility can surge other equipment in the facility if no suppressor is placed on each piece of equipment fed from a common electrical bus.

More about Low Voltage Surge Protection on CNC Applications:

Although the parallel connected three phase unit will give some protection to 120V or 24V power supplies and controls, for long term reliability and maximum up-time, the power supplies, circuit boards, and other electronic loads should be protected by a series installed low voltage SPD with enhanced filtering. This protection stage will eliminate anything that gets past the higher voltage three phase unit and in addition clean up all internally ring wave type transients that degrade your 120V and lower voltage electronics.

This combination of three phase and 120 or 24 volt units is field proven to offer the best protection and quickest return on investment (typically less than one year payback). Staged protection is in accord with IEEE (Institute of Electrical and Electronic Engineers) recommended staged protection. See IEEE Recommended Practices.

Why Surge Protect CNC Machines at Each CNC?

To best protect the machines/drives/motors, the TPX-480NN-F-100 unit provides great protection for the three-phase power directly feeding the machine. By installing this unit at each machine, you not only protect this machine from the rest of the facility, but you are also protecting the rest of the facility from this machine. Normal load switching of equipment inside any facility can surge other equipment in the facility if no suppressor is placed on each piece of equipment fed from a common bus. Plus, if lightning should strike the facility or near the facility and inductively couple onto building wiring, if no surge protective device (SPD) is installed near the equipment, lightning could get onto an overhead bus or get into a distribution panel and spread out to the other circuits on that bus or distribution panel. Also, if any electrical panel feeds parking lot lights, signs, security gates, rooftop HVAC equipment, or any other outside electrical equipment, lightning could strike at or near the outside equipment and travel back into the electrical panel inside the facility and then spread out to other equipment and other electrical panels in the building.

The Importance of Surge Protecting CNC Machines

Preventing Costly Downtime

CNC machines are vital in various industries, including manufacturing, aerospace, and automotive. Downtime due to machine failures can be incredibly costly, resulting in lost production time and revenue. TPD surge suppression filters help prevent disruptions caused by electrical surges, ensuring uninterrupted operation.

Safeguarding Precision Equipment

CNC machines operate with a high degree of precision, relying on intricate electrical and electronic components. Even minor voltage fluctuations can lead to inaccuracies, affecting the quality and consistency of manufactured products. TPD surge protection keeps these components safe from damage or degradation.

Protecting Against Damage

Electrical surges, whether from lightning strikes, power grid issues, or equipment switching inside the facility, can inflict irreversible damage on CNC machines. The repair or replacement of damaged components or entire machines can be expensive and time-consuming. TPD surge protection serves as a vital defense mechanism against such events.

Minimizing Product Loss

In precision manufacturing, material wastage can have a significant financial impact. When CNC machines malfunction due to electrical surges, the materials being worked on may be ruined. TPD surge protection helps minimize material losses by ensuring the machines function correctly.

Extending Equipment Lifespan

CNC machines are substantial investments, and their longevity is essential to maximize the return on investment. TPD surge protection not only prevents immediate damage but also contributes to the overall longevity of the equipment, reducing the need for frequent repairs or replacements.

Maintaining Reputation

For manufacturing companies, the reliability of CNC machines is directly tied to their reputation. Consistently producing high-quality products on schedule is crucial for maintaining customer trust and business relationships. TPD surge protection helps ensure this reliability.

Compliance and Safety

In some industries, compliance with safety standards and regulations is mandatory. TPD surge protection can help meet these requirements, ensuring a safe working environment and adherence to industry-specific guidelines.

TPD surge protection for CNC machines is essential for the protection of these precision instruments, preventing costly downtime, reducing material wastage, extending equipment lifespan, and maintaining a company's reputation in the competitive manufacturing industry. It's a smart investment that not only protects assets but also contributes to long-term financial stability and operational efficiency.